Qu'est-ce qu'un panneau PU ?

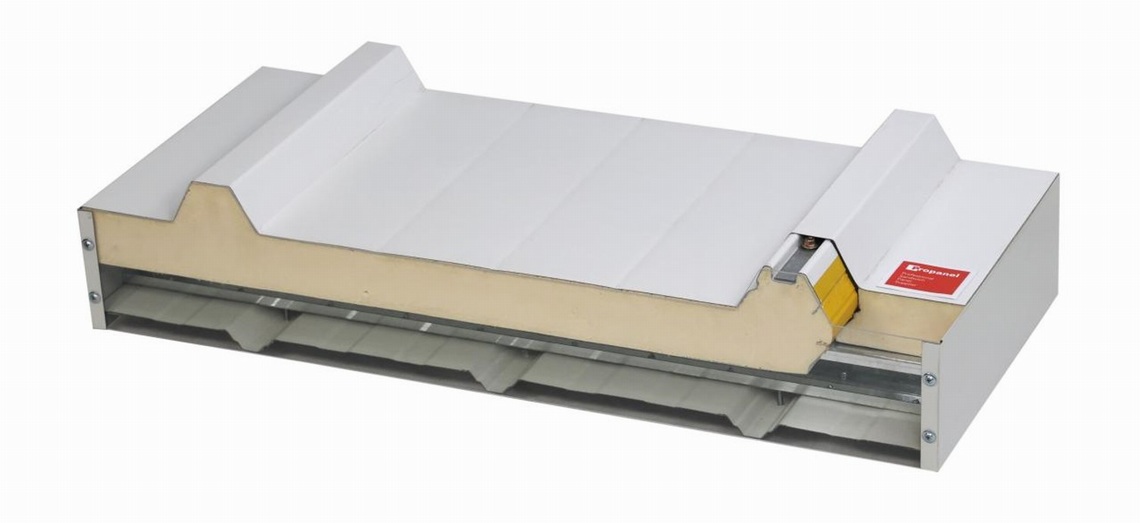

A Panneau sandwich en PU Il s'agit d'un panneau sandwich composé de deux couches extérieures (généralement des tôles métalliques, comme l'acier ou l'aluminium) entourant un noyau en mousse de polyuréthane (PU). Il est largement utilisé dans la construction de murs, de toitures et de cloisons en raison de son excellente isolation thermique, de sa légèreté et de sa durabilité.

Voici une ventilation concise

Composants:

1. Couches extérieures (peaux) : Les tôles minces et rigides (acier galvanisé ou aluminium) offrent une résistance structurelle, une résistance aux intempéries et une finition esthétique.

2. Noyau (mousse de polyuréthane) : La mousse PU, fournisseur de BASF, est un produit chimique doté d'un isolant haute performance et offre une faible conductivité thermique (généralement 0,02 à 0,025 W/m·K), ce qui la rend idéale pour le contrôle de la température.

Caractéristiques principales :

•Isolation: Efficacité thermique supérieure, adaptée aux applications telles que entrepôt frigorifique ou un logement pour volailles (de votre groupe 5).

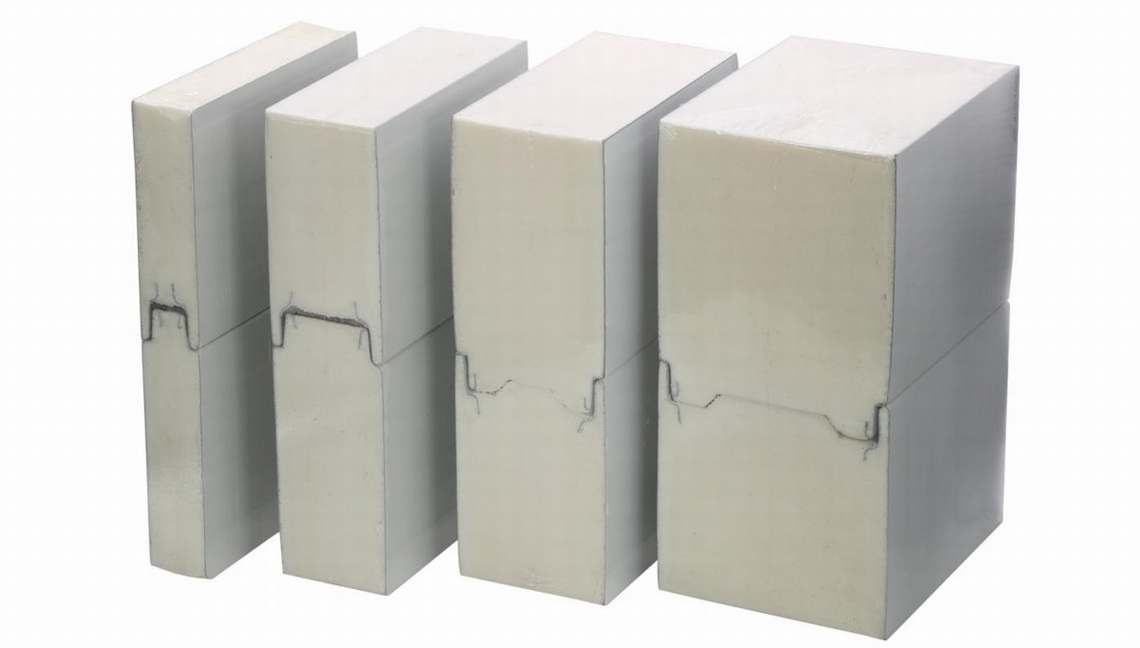

•Épaisseur: Les épaisseurs courantes comprennent 30 mm, 40 mm, 50 mm, 100 mm ou 150 mm, ce qui affecte les performances d'isolation.

•Applications : Utilisé dans les structures en acier, les ateliers automobiles 4S, les entrepôts frigorifiques et les systèmes de toiture/mur (Groupe 5), souvent avec des certifications telles que l'approbation CE ou FM

•Avantages : Léger, résistant au feu (dans une certaine mesure), facile à installer et rentable par rapport à d'autres matériaux comme le PIR ou la laine de roche.

•Limites: Moins résistant au feu que le PIR ; préoccupations environnementales en raison de la composition chimique du PU

Droit d'auteur

@ 2026 CHENGDU PROPANEL TECH CO., LTD. Tous droits réservés

.  RÉSEAU PRIS EN CHARGE

RÉSEAU PRIS EN CHARGE

Hi! Click one of our members below to chat on