Le matériau de construction idéal pour les économies d'énergie. Excellentes propriétés d'isolation et d'isolation thermique, avec une conductivité thermique de 0,024 à 0,041 W/m·K, permettant de réduire la consommation d'énergie. Léger et offrant un excellent maintien, il est facile à installer et rapide. Économique, il est très durable et possède également des propriétés imperméables et ignifuges. Il peut être personnalisé selon les besoins du bâtiment.

Numéro d'article :

EPSWALL0001Commande (MOQ) :

500 mPaiement :

USD 30% PPCouleur :

CustomizedDensité du matériau de base :

18 Kg/m³Port d'expédition :

Qingdao, ChinaDélai de mise en œuvre :

30-45 daysOrigine du produit :

Shandong, China

Caractéristiques | |

Taper | Panneau mural sandwich en polystyrène expansible |

Épaisseur | 50/75/100/120/150/200 mm |

Épaisseur de la peau métallique | 0,4 à 0,8 mm |

Largeur effective du panneau | 950/980 mm |

Densité | 8/10/12/14/16/18/20 kg/m³ |

Matériau de la peau | Bobine de PPGL, PPGI, acier inoxydable, aluminium |

Pré-peint | PE/SMP/HDP/PVDF etc. |

Qualité ignifuge | B2 |

Conductivité thermique | 0,042 |

Plage de température | -40~90℃ |

Longueur | Max 11,9 m ou personnalisé. |

La conception personnalisée est la bienvenue. | |

Excellentes propriétés d'isolation thermique et de conservation de la chaleur, réduisant les coûts de consommation d'énergie

La conductivité thermique du matériau de base en PSE est extrêmement faible (généralement ≤ 0,041 W/(m·K)), bien supérieure à celle des murs en briques traditionnels (conductivité thermique d'environ 0,81 W/(m·K)). Il permet de bloquer efficacement le transfert de chaleur entre l'intérieur et l'extérieur, favorisant ainsi les économies d'énergie et la protection de l'environnement, et s'inscrivant dans le concept de bâtiments écologiques et économes en énergie.

Léger et très résistant, réduisant la charge structurelle

La densité du matériau principal en PSE est de seulement 8 à 28 kg/m³. Associé à des panneaux métalliques, le poids total du panneau est bien inférieur à celui d'un mur en briques de même épaisseur (environ 190 kg/m³). Ce matériau léger permet non seulement de réduire les coûts de construction des fondations, mais aussi d'éviter les risques liés à un poids structurel excessif. De plus, la couche extérieure en tôle d'acier colorée offre une grande résistance aux chocs et à la déformation, capable de supporter des chocs mineurs lors d'une utilisation quotidienne, garantissant ainsi la stabilité à long terme du mur.

Effet d'isolation acoustique exceptionnel, améliorant le confort de l'espace

La structure interne du noyau en EPS est en nid d'abeille fermé, ce qui permet d'absorber efficacement les ondes sonores et de réduire la transmission du bruit. L'isolation phonique aérienne d'un EPS ordinaire panneaux muraux L'isolation acoustique peut atteindre plus de 40 dB. L'utilisation d'un matériau de base à double couche ou d'une couche de surface spéciale permet d'augmenter l'isolation acoustique à plus de 45 dB.

La résistance au feu répond aux normes, garantissant la sécurité d'utilisation

Grâce à l'ajout de retardateurs de flamme, les panneaux muraux en PSE peuvent atteindre le niveau B1. De plus, le matériau principal en PSE ne produit pas de gaz toxiques lorsqu'il est chauffé et dégage moins de fumée en brûlant, ce qui permet de prolonger le temps d'évacuation du personnel et d'améliorer encore le coefficient de sécurité du bâtiment.

Construction pratique et efficace, raccourcissant la période de construction

Les panneaux muraux en PSE sont pour la plupart des éléments standardisés préfabriqués en usine, et leurs bords latéraux sont conçus avec des assemblages à rainure et languette ou à tenon et mortaise. La construction sur site ne nécessite que des épissures et des fixations à l'aide de boulons et d'éléments de connexion, ce qui réduit le temps de construction de plus de 60 %. De plus, le panneau est léger et ne nécessite aucun équipement de levage lourd. Le transport et l'installation manuels sont possibles, ce qui réduit considérablement les coûts de construction et les délais.

Forte résistance aux intempéries, réduisant l'entretien ultérieur

Le matériau de base en EPS présente une bonne stabilité chimique et résiste aux facteurs environnementaux tels que l'humidité, les températures élevées et les conditions acido-basiques. Il est peu susceptible de présenter des problèmes tels que la moisissure, la corrosion ou les fissures après une utilisation prolongée. La couche extérieure de la plaque d'acier colorée est généralement galvanisée ou peinte par pulvérisation, ce qui lui confère une excellente résistance à la corrosion et une durée de vie de 15 à 20 ans en extérieur. Après l'installation du panneau mural en EPS, les coûts d'entretien ne représentent que le tiers à la moitié de ceux des murs en briques traditionnels, ce qui permet aux utilisateurs de réaliser d'importantes économies de main-d'œuvre et d'investissement.

Charge verticale admissible et coefficient de transfert de chaleur de PROPANEL Panneau de toiture sandwich EPS (déflexion admissible f ≤ L/240)

Épaisseur (mm) | Transfert de chaleur (W/㎡·k) | Poids | Charge P=KN/m2 | 0,6 | 0,8 | 1 | 1.2 | 1,5 |

50 | 0,64 | 10 | L(m) | 6,5 | 5.8 | 5.1 | 4.6 | 4 |

75 | 0,43 | 10h45 | L(m) | 7.8 | 7 | 6.2 | 5.6 | 5 |

100 | 0,32 | 10,9 | L(m) | 9,5 | 8,5 | 7,5 | 6.8 | 6 |

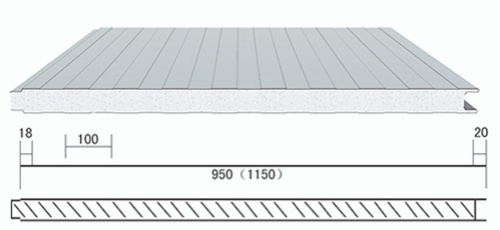

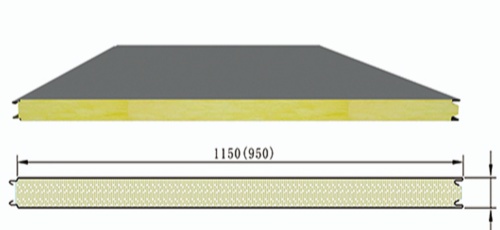

3 types de joints pour panneaux muraux sandwich EPS

Il existe 2 types de type de recouvrement pour le panneau sandwich mural EPS : l'un est de type capuchon, l'autre est de type chevauchement.

Les images sont comme ci-dessous :

Panneau mural de type prise 950 1150

Panneau mural S-Socket Type 950 1150

4 Application du panneau sandwich mural EPS

Les panneaux muraux EPS sont largement utilisés dans l'industrie de la construction en raison de leur légèreté, de leurs propriétés isolantes, insonorisantes et ignifuges.

Dans les bâtiments industriels, ils constituent le choix privilégié pour les murs d'installations industrielles. Leur légèreté permet de réduire la charge sur la structure principale et les coûts. Leur bonne isolation permet de réduire la consommation d'énergie liée à la climatisation et au chauffage, ce qui les rend adaptés aux ateliers nécessitant une température élevée. De plus, leur facilité d'installation permet de raccourcir les délais de construction et de répondre aux besoins de production rapide des entreprises.

Dans les bâtiments civils, ils sont principalement utilisés pour les résidences basses, les maisons rurales auto-construites et les maisons préfabriquées. Les murs extérieurs offrent une excellente isolation phonique, améliorant le confort de vie ; les murs intérieurs permettent de réduire l'épaisseur des murs et d'augmenter la surface utile. Grâce à l'ajout de retardateurs de flamme, ils atteignent le niveau de résistance au feu B1, sont conformes aux normes de sécurité incendie, offrent une excellente résistance aux intempéries et permettent de réduire les coûts d'entretien ultérieurs.

Dans les bâtiments publics, on les retrouve couramment dans les bureaux de vente temporaires, les salles de classe temporaires dans les écoles et les services d'isolement dans les hôpitaux. La préfabrication en usine et l'assemblage sur site permettent de réaliser un bâtiment de 100 m² en 3 à 5 jours. Après démontage, certains panneaux sont réutilisables, ce qui est conforme au concept de construction écologique. Leurs performances d'isolation permettent de maintenir une température intérieure adéquate.

De plus, ils sont utilisés dans le stockage de la chaîne du froid pour réduire les pertes de chaleur et diminuer la consommation d'énergie ; dans les serres agricoles, ils aident à maintenir des températures stables et sont résistants à la corrosion, capables de résister à l'érosion environnementale due à une humidité élevée.

5 cas de projets de panneaux muraux sandwich EPS

Exemples de projets de panneaux muraux sandwich EPS – Entrepôt logistique brésilien

Projets de panneaux sandwich EPS pour toitures - Usine japonaise d'équipements électroniques

Droit d'auteur

@ 2026 CHENGDU PROPANEL TECH CO., LTD. Tous droits réservés

.  RÉSEAU PRIS EN CHARGE

RÉSEAU PRIS EN CHARGE

Hi! Click one of our members below to chat on